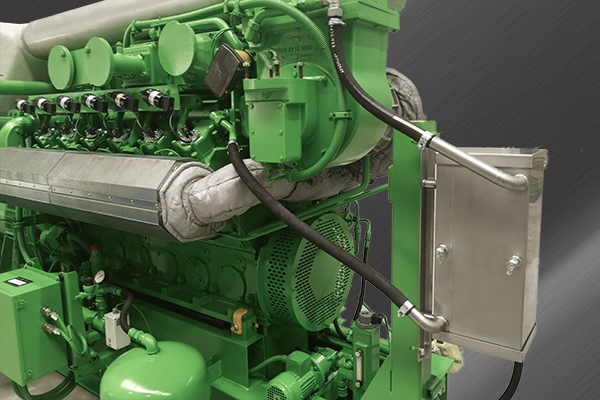

Jenbacher J316

Crankcase ventilation of

combustion engines

Jenbacher Series 3

Since 2017, HEINZMANN IFT has been taking on the challenge of retrofitting Jenbacher Series 3 gas engines, some of which are in the field without oil mist separators, in order to achieve improvements in terms of both maintenance and engine efficiency.

Highly efficient crankcase ventilation systems for this type of engine are now being used successfully in many cases and are offered as retrofit or conversion solutions.

Product lifetimes of 30,000 operating hours without maintenance are achieved as standard.

Engine power: 850 kW

Longest validated service life: 45,000 operating hours

Oil content of the filtered blow-by gas: 0.5 mg/m³